In the ever-evolving landscape of industrial manufacturing, the year 2023 has unveiled a unique avenue of opportunity—the exploration of investment casting foundries for sale. This intriguing proposition takes the spotlight as entrepreneurs, investors, and industry enthusiasts cast their gaze upon the fusion of tradition and technology. At the heart of this transformation lies the profound impact of Computer Numerical Control (CNC) technology, which has reshaped the investment casting industry and breathed new life into these foundries.

As we delve into the intricate world of investment casting foundries for sale, we find ourselves at the nexus of craftsmanship and innovation. The heritage of investment casting—a time-honored method that traces its origins back centuries—intersects with the cutting-edge capabilities of CNC technology, creating an environment ripe with potential. This exploration is not just about buying and selling businesses; it’s about embracing the future of manufacturing, where precision, efficiency, and quality converge.

In the pages that follow, we will navigate the historical underpinnings of investment casting, the role of CNC technology in revolutionizing this age-old practice, and the myriad of opportunities that arise as investment casting foundries become available for purchase. We will venture into the realm of CNC integration, where established businesses can find new vigor and aspiring industrialists can carve their path to success. It’s a journey where tradition meets transformation, and where the seeds of growth are sown with the precision of CNC precision.

Through this exploration, we aim to shed light on the investment casting foundries for sale, a landscape that holds the promise of growth, innovation, and prosperity. The fusion of CNC technology with the heritage of investment casting presents a remarkable opportunity to redefine the industry, ushering in a new era of manufacturing excellence. So, let us embark on this voyage, as we unveil the possibilities and potentials that lie within the world of investment casting foundries for sale, powered by the prowess of CNC technology.

Investment Casting: A Tradition Meets Technology

Investment casting, also known as lost-wax casting, stands as a testament to the ingenuity of human craftsmanship through the ages. Rooted in history, this manufacturing method has been a cornerstone of creating intricate and finely detailed metal parts. The process begins with a meticulously crafted wax pattern, which is coated in ceramic to form a mold. Molten metal is then poured into the mold, replacing the wax and giving shape to the final product.

The historical context of investment casting traces back to ancient civilizations, where it played a pivotal role in creating jewelry, ornaments, and artistic pieces. From ancient Mesopotamia to ancient Egypt and beyond, artisans honed their skills to transform wax patterns into metallic masterpieces. Over the centuries, the technique evolved, adapting to the changing needs of various industries, from art to aerospace.

In the realm of investment casting, precision and attention to detail have been paramount. Skilled craftsmen have relied on their expertise to ensure that every intricate design and delicate feature of a wax pattern translates seamlessly into the final cast product. The process has held its ground even as technological advancements have swept through the manufacturing landscape.

The convergence of tradition and technology is where the true magic lies. While the core principles of investment casting remain unchanged, the advent of CNC technology has ushered in a new era of precision and efficiency. The meticulous handwork of artisans is now amplified by the power of CNC precision, breathing life into the complex geometries and fine details of castings that were once thought challenging to achieve.

As we move forward in our exploration, we’ll unravel how CNC technology has redefined the landscape of investment casting, paving the way for investment casting foundries to become prime opportunities for those seeking to harness the synergy of tradition and innovation.

CNC Revolution in Investment Casting

In the dynamic world of manufacturing, change is the only constant, and the integration of CNC technology into investment casting processes stands as a testament to this axiom. The CNC revolution has breathed new life into the traditional art of investment casting, reshaping it into a precise, efficient, and cutting-edge process.

CNC, which stands for Computer Numerical Control, entails the use of computer-guided machines to automate and control various manufacturing operations. When applied to investment casting, CNC technology injects a dose of accuracy, repeatability, and efficiency that was previously unattainable through manual methods alone.

One of the key areas where CNC has made a significant impact is in pattern making. Creating wax patterns with intricate designs and precise dimensions is a painstaking task. However, CNC machines equipped with advanced software can effortlessly translate digital designs into intricate wax patterns with unparalleled accuracy. This not only reduces the likelihood of human errors but also opens the doors to creating intricate patterns that were once deemed too complex to execute.

Furthermore, CNC technology brings consistency to the investment casting process. Reproducing intricate designs with precision and accuracy becomes second nature, ensuring that each casting is a faithful replica of the original design. This level of consistency is particularly crucial for industries that require a high degree of conformity, such as aerospace and automotive manufacturing.

Additionally, CNC technology allows for the optimization of material usage. By precisely controlling the amount of material deposited, wastage is minimized, leading to cost savings and a more sustainable approach to manufacturing. This efficiency also extends to production times, as CNC-guided processes significantly reduce the time required for each casting cycle.

Beyond its technical advantages, the integration of CNC technology is a strategic move that positions investment casting foundries at the forefront of innovation. This not only appeals to industries that demand precision and quality but also opens doors to new opportunities in markets that were previously out of reach.

As we delve deeper into our exploration, we will uncover the potential opportunities and transformations that CNC technology brings to investment casting foundries that are up for sale. This revolution is more than just an upgrade; it’s a paradigm shift that marries tradition with technology, forging a path to excellence in the world of manufacturing.

Opportunities in Investment Casting Foundries for Sale

The world of investment casting foundries is witnessing a transformational shift in 2023, and for those considering venturing into this industry, the opportunities are both compelling and promising. Investment casting foundries for sale offer a unique gateway into a sector that is being rejuvenated by the infusion of CNC technology. Let’s delve into the various investment prospects that these foundries present and explore the allure of combining tradition with innovation.

Investment casting foundries, often rooted in a rich history of craftsmanship, provide a solid foundation for potential buyers. The availability of established businesses comes with numerous benefits, including existing customer relationships, trained staff, and proven operational processes. However, what sets apart the investment casting foundries of today is their openness to embracing CNC technology, which has the potential to exponentially enhance these advantages.

The integration of CNC technology introduces a new level of precision, efficiency, and scalability to investment casting processes. For buyers of foundries, this translates into a streamlined path towards achieving operational excellence. The ability to produce complex and intricate castings with reduced lead times becomes a significant selling point, appealing to industries that demand high-quality components.

Furthermore, investment casting foundries equipped with CNC capabilities open doors to diversification. Traditional markets, such as aerospace and automotive, continue to demand intricate and reliable cast components. However, the application of investment casting has expanded into sectors such as medical devices, energy, and even artistic creations. This diversification not only broadens the potential customer base but also mitigates risks associated with over-dependence on specific industries.

In the realm of investment casting foundries for sale, the inclusion of CNC technology amplifies growth prospects. Buyers are not just acquiring a business; they are acquiring the means to elevate their offerings, tap into new markets, and stay competitive in an evolving landscape. This integration is a strategic move that positions buyers as innovators, capable of delivering precise, complex, and high-quality castings to a demanding market.

As we journey deeper into this exploration, we will unveil the intricacies of integrating CNC technology into existing investment casting foundries for sale. The convergence of tradition and innovation is not just an opportunity for growth; it’s a gateway to shaping the future of precision manufacturing, casting a legacy that marries time-honored craftsmanship with the power of technology.

Integration of CNC in Foundries for Sale

The integration of CNC technology into existing investment casting foundries for sale marks a turning point in the industry’s evolution. This harmonious convergence of tradition and innovation empowers buyers to embark on a journey of transformation and growth. Let’s delve into the dynamic process of integrating CNC technology into these foundries and explore how it can reshape their operations and offerings.

The infusion of CNC technology brings a wave of positive change to investment casting foundries. One of the most noticeable advantages is the remarkable improvement in casting quality. CNC-driven processes ensure precision at every step, resulting in consistent, defect-free castings. This level of quality assurance not only meets industry standards but also instills confidence in customers who seek reliable and impeccable components.

Reduced lead times are another noteworthy benefit that CNC technology bestows upon investment casting foundries. Traditional casting methods often involve time-consuming manual processes, leading to longer production cycles. With CNC integration, tasks such as pattern making, mold creation, and finishing are expedited, enabling foundries to fulfill orders swiftly without compromising on quality.

Moreover, the integration of CNC technology grants investment casting foundries the capacity to explore new dimensions of design complexity. Complex geometries, intricate patterns, and delicate details that were once challenging to replicate can now be realized with ease. This newfound design flexibility opens doors to a broader range of applications across various industries, from aerospace to medical devices.

Material optimization is yet another facet that benefits from CNC integration. With precise control over machining and material removal, foundries can reduce wastage, thus contributing to cost savings and sustainability. This is a significant consideration in an era where environmental consciousness is a driving force in industrial decision-making.

The integration process itself involves careful planning and adaptation. Training existing personnel to operate CNC machinery effectively is crucial. While some tasks will be automated, the human touch of craftsmanship remains invaluable, especially in areas where intricate finishing is required. The coexistence of skilled artisans and modern technology creates a synergistic environment where the best of both worlds unite.

As we explore the integration of CNC technology into investment casting foundries for sale, we’ll uncover the steps and strategies that lead to a seamless transition. We’ll also shed light on real-world examples of foundries that have successfully harnessed CNC’s capabilities to elevate their operations and offerings. This integration is not just a transaction; it’s a transformation that paves the way for investment casting foundries to excel in a dynamic and competitive landscape.

Leveraging CNC for Innovation

The integration of CNC technology into investment casting foundries for sale is not merely a technological upgrade; it’s an invitation to explore new horizons of innovation and diversification. This integration empowers buyers to take calculated risks, expand their product offerings, and tap into untapped markets. Let’s delve into the possibilities that CNC technology opens up for innovative thinking and business growth.

One of the most exciting aspects of CNC integration is the ability to explore new markets and industries. Investment casting, once confined to specific applications, can now branch out into uncharted territories. The precision and adaptability of CNC technology enable foundries to cater to sectors they may not have considered viable before. From producing intricate components for the medical field to crafting specialized parts for the renewable energy sector, CNC-equipped foundries have the agility to pivot and thrive in emerging markets.

Material exploration is also enhanced by CNC integration. Buyers of investment casting foundries for sale can experiment with a wider range of materials, alloys, and compositions. CNC technology facilitates the machining and casting of intricate structures from diverse materials, leading to the creation of components with enhanced properties and performance characteristics. This flexibility in material selection can be a game-changer, especially in industries that demand specific attributes such as corrosion resistance, lightweight construction, or high-temperature tolerance.

The realm of design innovation is another frontier that CNC technology beckons. The intricate geometries and complex patterns that can be achieved through CNC precision casting are not limited to functional parts alone. Investment casting foundries can now delve into the creation of artistic and aesthetic pieces that were once thought to be out of reach. Sculptures, decorative elements, and ornamental components can be brought to life with unparalleled accuracy and intricacy, showcasing the fusion of artistry and technology.

Moreover, the integration of CNC technology fosters a culture of continuous improvement and experimentation. Foundries can embrace lean manufacturing principles and apply data-driven insights to refine their processes and offerings. The digital nature of CNC allows for detailed tracking and analysis, enabling informed decisions that optimize efficiency, reduce waste, and enhance overall productivity.

The synergy between CNC technology and investment casting craftsmanship enables foundries to evolve without losing their essence. While the technology streamlines operations and enhances precision, the touch of skilled artisans ensures that each piece remains a work of art. This harmonious blend of tradition and innovation results in products that carry both the weight of heritage and the promise of progress.

As we navigate the landscape of investment casting foundries for sale, we’ll explore how CNC technology opens doors to innovation and expansion. We’ll delve into real-world examples that showcase the transformative potential of CNC integration, and we’ll emphasize how this marriage of technology and creativity empowers foundries to pioneer new frontiers and leave a lasting mark on the industry.

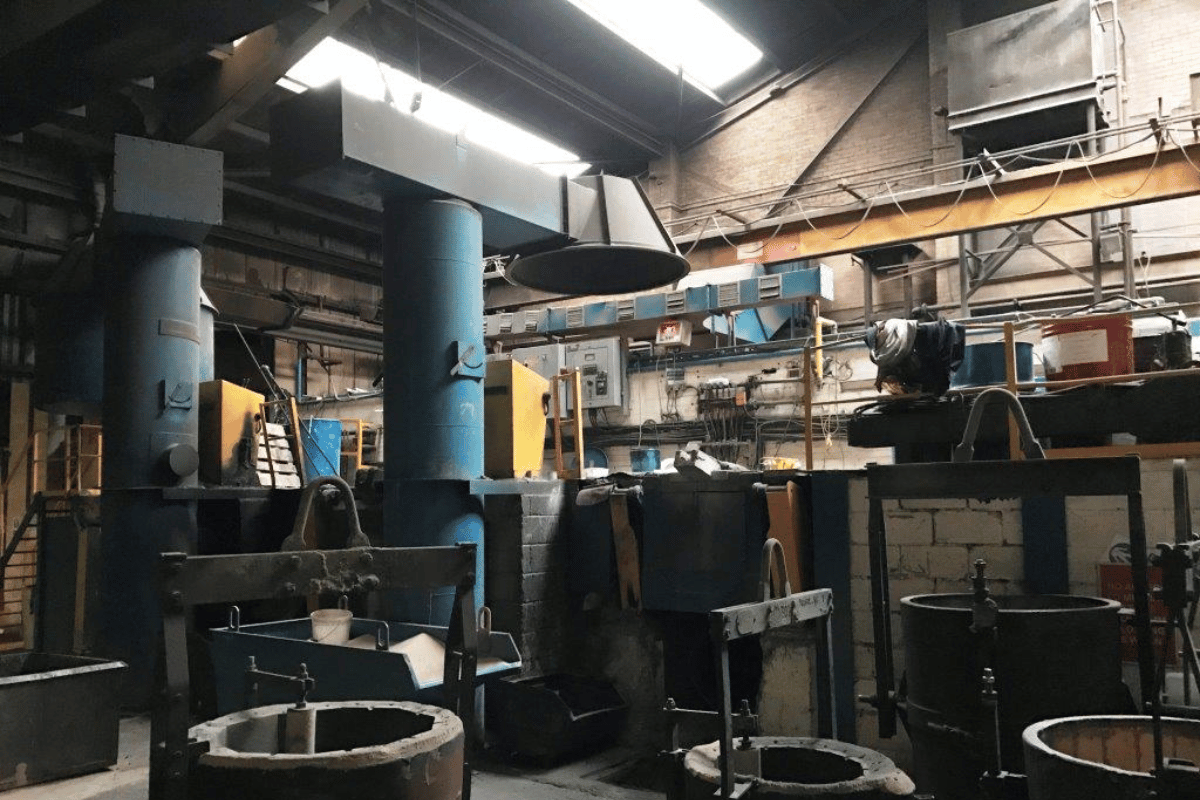

Signicast Investment Casting Foundry | Wisconsin, USA

Conclusion: Navigating Opportunities with CNC

In the ever-evolving world of manufacturing and investment casting, the integration of CNC technology has emerged as a transformative force, propelling investment casting foundries for sale into a new era of innovation and growth. As we conclude our exploration of this dynamic landscape, let’s recap the key insights and opportunities that CNC technology brings to the forefront.

Investment casting, deeply rooted in tradition and craftsmanship, is undergoing a remarkable evolution. The introduction of CNC technology has redefined precision, accuracy, and efficiency in the casting process. This technology empowers foundries to produce intricate and complex components with unparalleled detail and consistency. The ability to achieve intricate geometries, intricate patterns, and high-quality surface finishes opens up a myriad of possibilities across diverse industries.

For those considering investment casting foundries for sale, the integration of CNC technology represents more than just an upgrade—it’s a gateway to opportunities. The potential for growth, diversification, and tapping into new markets is unprecedented. CNC-equipped foundries have the flexibility to adapt to emerging trends and demands, expanding their reach and establishing themselves as leaders in their chosen sectors.

One of the standout advantages of CNC integration is its role in bridging the gap between craftsmanship and innovation. Artisans and CNC experts collaborate seamlessly, combining the finesse of traditional craftsmanship with the precision of modern technology. This fusion allows foundries to uphold their artistic legacy while embracing the advancements that CNC offers, creating a unique blend that captivates both purists and tech enthusiasts.

Furthermore, the integration of CNC technology fosters a culture of continuous improvement and adaptability. With data-driven insights and real-time monitoring, foundries can optimize their processes, reduce waste, and enhance overall efficiency. This leads to streamlined production, shortened lead times, and improved resource management, all of which contribute to a more competitive and agile business model.

As we navigate the opportunities presented by investment casting foundries for sale, it’s evident that CNC technology has unlocked a new chapter in the industry’s story. The precision, accuracy, and innovation offered by CNC integration are poised to redefine the limits of what’s achievable in investment casting. By embracing this technology, buyers can step into a realm of endless possibilities, where tradition and technology converge to create a legacy that resonates through the ages.

In conclusion, the journey through investment casting foundries for sale with CNC integration is a journey of transformation, growth, and artistic evolution. By embracing CNC technology, buyers can embark on a path that not only upholds the heritage of investment casting but also pioneers a future where precision and innovation are the cornerstones of success. As we bid farewell, we invite you to explore the potential, seize the opportunities, and become a trailblazer in this exciting era of investment casting excellence.